MAKINO FFAUT

Basic Functions

- Rough machining

- Semi-finish machining

- Finish machining

- Machining database

- Other Machining functions

- Other functions

- Simulator

Products

Basic Functions

Other Machining Functions

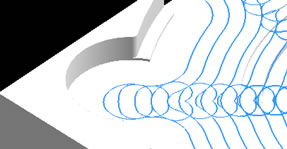

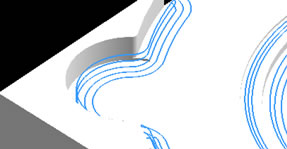

Trochoidal Machining

Trochoidal (spiral) motion is performed where the cutting load increases.

The trochoidal machining function enables high-speed machining with end mills.

CR Machining

CR machining creates toolpath for the area that can not be machined at previous machining.

Flat Face Machining

FF/cam automatically detects the flat areas of the workpiece geometry and generates toolpaths only for those surfaces.

Flat Edge Machining

FF/cam automatically detects the flat areas and section edges of the workpiece geometry, and generates toolpaths only for the edges of the flat surfaces.

2D Profile Machining

FF/cam generates toolpaths on simple profile lines. This function is also used to generate a path for the tool radius offset code.

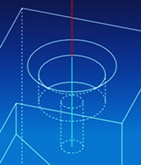

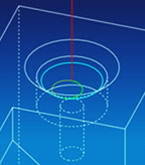

Drilling

FF/cam supports drilling with tools such as drills, taps, reamers, boring tools, and chamfering cutters.

Drilling Function

- FF/cam generates drilling data for canned-cycle machining and profile machining.

- FF/cam automatically searches 3D machining models for the positions and depths of holes to register them.

Canned Cycle |

Chamfering (Profile Machining) |

Spot Facing (Outward) |

Helical Milling |

Thin Rib Machining

-

FF/cam generates special toolpaths for machining copper electrodes and thin ribs.

-

Toolpaths exclusively for machining thin ribs are generated while the tool load is taken into account during machining.

-

Toolpaths for "deflection-free" rib machining can be generated by making a simple setting.

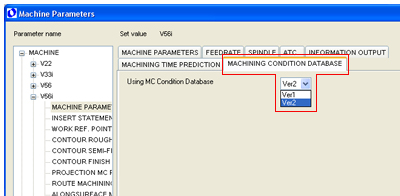

Machining Conditions

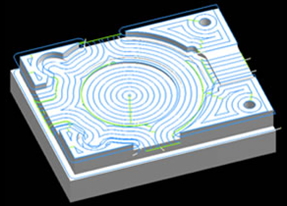

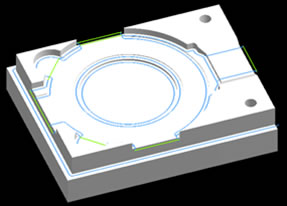

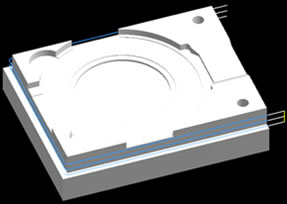

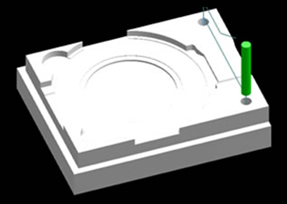

Makino develops the simulator for high speed machining.

It shows following;

- The collision check between tool holder and workpiece

- Tool movement

- The model of machining remain by color

Makino Milling Machine Co.Ltd.

Machining System Division

MAIL: ugi-sp@makino.co.jp