Basic Functions

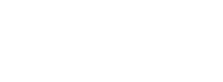

Machining condition can be set easily

Just specified a material, tools and a machine, suitable machining conditions are indicated. Even if an operator is not yet experienced, he/she can operate the high-speed machining program.

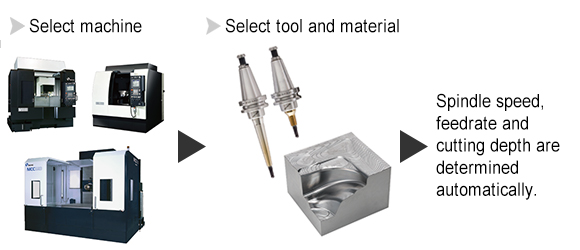

Optimize PC perfomanse

Efficient implementation is possible in NC data generation for large shape or sophisticated shape that require huge volume of calculations.

Versatile functions

Major Functions

- Along surface machining

- Contour Z spiral motion

- Rough contour machining

- Flat machining

- Smooth Cornering movement

- Stock Machining

- 20 Route Machining

- Contour projection machining

- Contour Finish Machining

- Drilling

- 3D equi-pitch machinig

- Core/ Pocket Machining

- 30 Curve Machining

- Trochoidal machining

- Flat Edge Machining

- Contour Projection Machining

- Burr Removing Operation

- Corner Edge

- Contour Gap Machining

etc……..

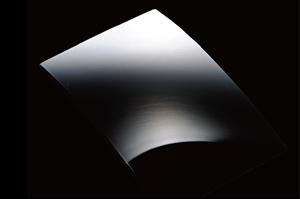

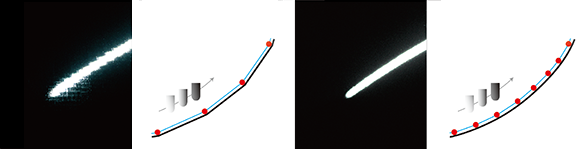

Optimization of tolerance values

Setting smaller tolerance values in NC programs results in smooth machine motions which produce smooth machined surfaces.

Smaller tolerances also mean smaller angle changes between NC blocks.

So the machine can decelerate less at corners, which has direct effect to reduce the machining time.

Right: Tolerance values ±0.0001 mm

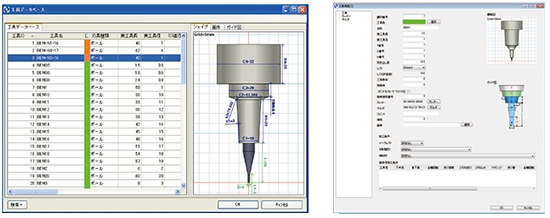

Machining Database

Makino has made a database of machining conditions based on the FF machining theoretics.

These machining conditions has been generated the accumulated machining results.

Machining Conditions Database

For example, the FF machining condition database has over 2,000 types of machining conditions only for solid ball end mills.

And It has one for carbon steel, pre-hardened steel, high hardness steel and aluminum.

Depending on the tool diameter and length, it selects best condition for machining time, accuracy and tool life.

(It selects spindle speed, feed rate and feed amount.)

Tool/holder database and cutting condition database by tool Manufacturers

Register the tools data and reference cutting conditions offered by tool manufacturers and tools data used by user frequently.

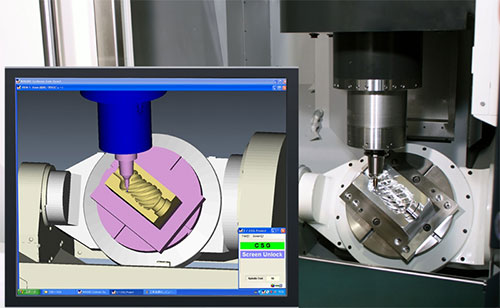

Data Output Function for Collision Safeguard

By using this function (data output function for Collision safeguard), the necessary data can be output from FFAUT to Collision safeguard.

With this function, flow of machining from FFAUT to Collision safeguard becomes smooth.

What is Collision Safeguard?

It is a software which prevents interference and damage from occurring in the machining chamber of the machining center.

While the machining is in progress, “Machine Operation Prediction” and “Simulation” are performed and the machine is stopped before collisions occur.

[Collision safeguard] is an option of the machine (machining center). For details, please contact your sales representative.