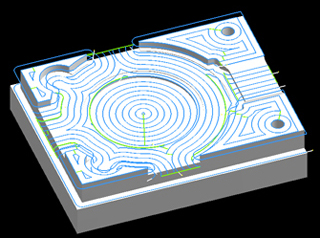

Rough Machining

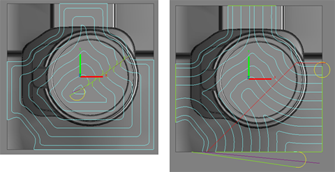

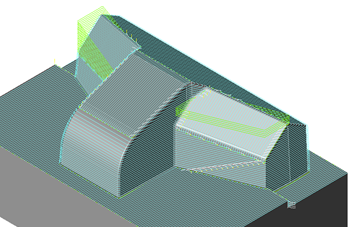

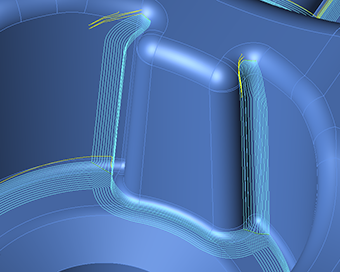

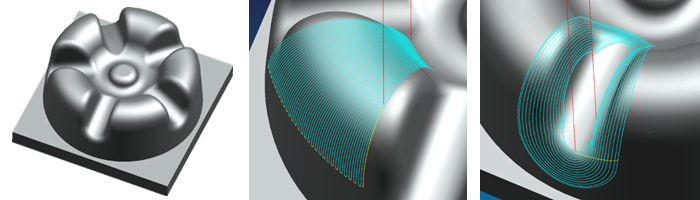

Contour Rough Machining

In Rough Machining, Create the cutter path to reduce the tool load.

Automatically changes inward or outward motion to match the machining geometry.

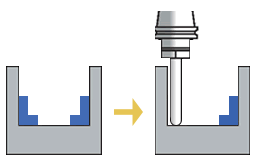

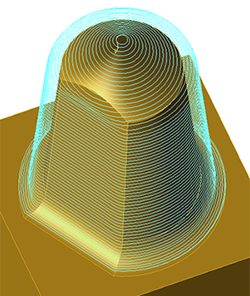

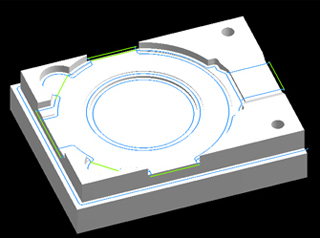

Holder and Shank Interference Check

FFAUT automatically determines the area which can be machined with specified tool.

It divides the area that can be machined by tool with short overhang length and long one.

By dividing area, machining time gets shorter.

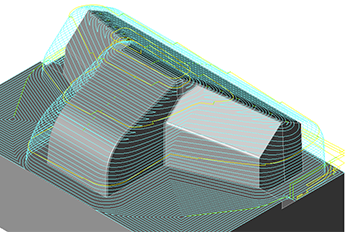

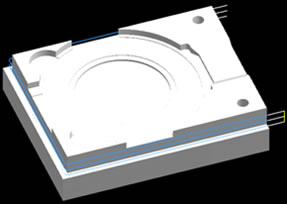

Stable Machining

To ensure stable rough machining, the “half-pitch shift” function is available for extending tool life by preventing chipping due to a sudden change in the amount of stock being removed.

The half-pitch shift function automatically generates a toolpath that shifts the tool half a

Half Pitch Shift

To ensure stable rough machining, the “half-pitch shift” function is available for extending tool life by preventing chipping due to a sudden change in the amount of stock being removed.

The half-pitch shift function automatically generates a toolpath that shifts the tool half a pitch from the previous path.

Automatic Insertion of Corner Radii

Corner radii are automatically inserted in the corner portions of the toolpath. This function prevents tool damage due to sudden changes in the tool load.

Semi-Finish Machining / Finish Machining

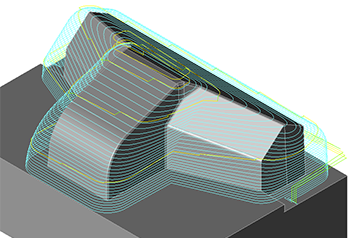

Contour Projection Machining

It switches between contour machining and projection machining automatically depending on the inclination angle of the geometry surface.

Finishing of complex geometry can be automated efficiently.

Contour Z Spiral Machining

Make a spiral tool path based on the tool path of contour machining.

Optimized for high-precision machining. Especially effective for small mold machining like lens or electrodes.

Contour Finish

Creates contour paths to form uniform steps on the specified cross-section.

This results in a highly uniform machined surface that readily facilitates additional machining with fine tools in subsequent operations.

Corner R Machining

This toolpath is to find the machining remain from a former machining automatically and creates appropriately.

Both of contour and along the surface movement can be applied for areas with different pitches.

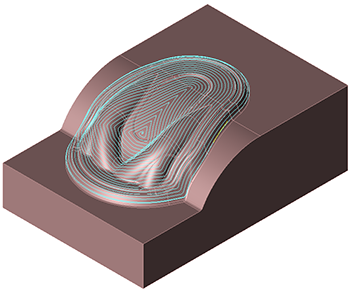

3D Equi-Pitch Machining (Close)

Make a equally tool path fit on the geometry that was based on setting one group of closed curves.

For geometry machines by regular inward/outward motion.

Curve lines and edges of solid models are required as different elements.

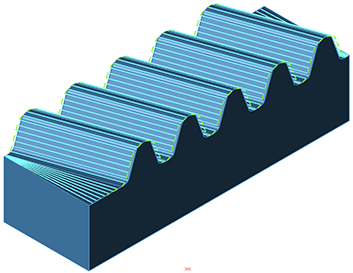

3D Equi-Pitch Machining (Open)

It is uniformly processed according to the selected open loop curve.

It is useful for shapes with sudden rises and falls.

Curve lines and edges of solid models are required as different elements.

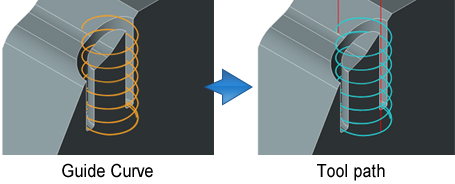

3D Curve Machining

[3D curve machining] sets the curve as the target for machining and generates a tool path along the curve.

“Every curve” shorten the machining time.

Because it is move less between the guide curves and it is intensively machining one of the guide curves.

Along Surface machining

FFAUT creates smooth toolpath to several surfaces.

Gap Machining

FFAUT creates toolpath that is few machining remain at smooth surface. Contour Gap Machining is notably effective for die cast dies with their highly convex-concave geometry.

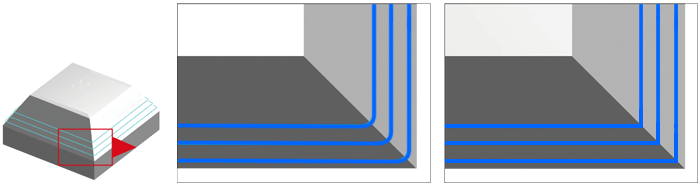

Corner Edge (Contour Machining and Scan Machining)

The corner edges become sharp.

It is effective for parting line, slide and edge.

Right side figure : With contour corner edge

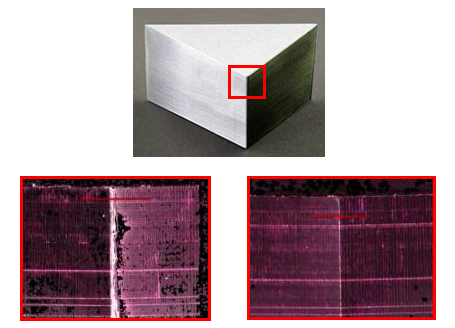

Burr Removing Operation

Repeated path on each Z level.

Effective for tiny portion with deburring or polishing.

Left ; Machining for One time

Right ; Burr removing operation : ON

Repeated cutting frequency : 1

2D Machining

Flat Face Machining

FFAUT automatically detects the flat areas of the workpiece geometry and generates toolpaths only for those surfaces.

Flat Edge Machining

FFAUT automatically detects the flat areas and section edges of the workpiece geometry, and generates toolpaths only for the edges of the flat surfaces.

2D Profile Machining

FFAUT generates toolpaths on simple profile lines. This function is also used to generate a path for the tool radius offset code。

It is also available only 2D.

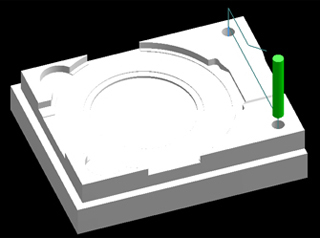

Drilling

FFAUT supports drilling with tools such as drills, taps, reamers, boring tools, and chamfering cutters.

It is also available only 2D.

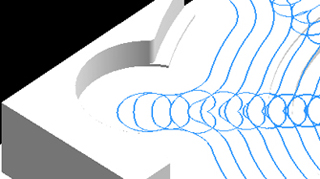

Trochoidal Machining

Trochoidal (spiral) motion is performed where the cutting load increases.

The trochoidal machining function enables high-speed machining with end mills.

Core / Pocket Contour-step Machining

Only specify the outline and parameter, can make a toolpath of Contour-step machining on core・pocket geometry of 2 – 2.5D.

It is also available only 2D.