Machining that maximizes the advantages of additional axes

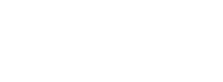

Index roughing

Designed for machining uncut portions without any wasted motion.

The workpiece can be indexed to the optimal angle for each machining area.

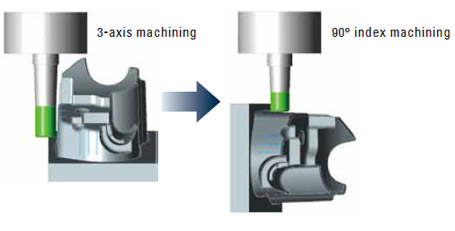

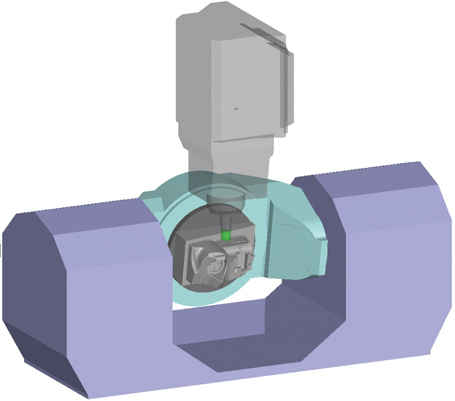

Index Semi-Finish Machining, Index Finish Machining

The workpiece is indexed to the optimal angle to avoid cutting with

the tool tip.

This produces superb machined surface quality.

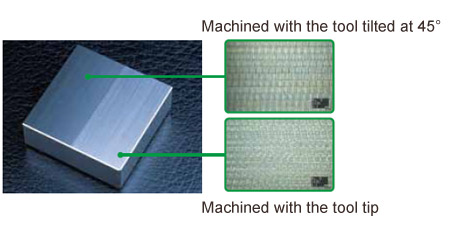

Function for specifying the machining direction

Function for specifying direct numerical input

This feature enables the operator to specify the machine’s indexing angle as desired,making it easier to check the machining area.

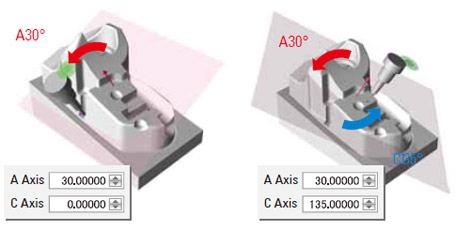

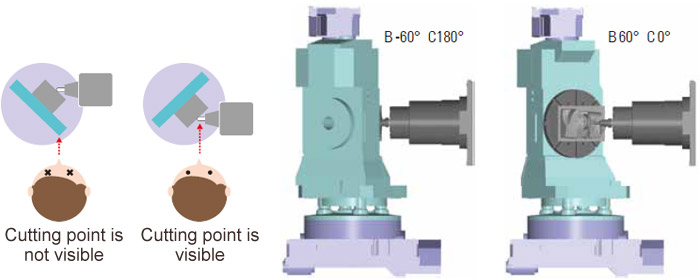

Function for changing the machine orientation

There are times when two indexing angle patterns are possible, depending on the machine structure.

The operator can select the machine orientation that allows easy checking of the machining area.

unction for specifying the surface pick feed direction

This feature is handy for machining inclined flat surfaces.

Function for checking machine orientation

Machine orientation check

Interference checks can be done that include not only the tool and workpiece but also machine structural elements.

Stroke check and minimum increment check

Whether a set indexing angle is compatible with the machine specifications or not can be confirmed before running the toolpath calculations.

Supporting various control functions

- This function supports “Tilted working indexing plane command” that enables to do machining on any desired tilted work plane with 3-axis NC program.

It facilitates machining operations of 2+3 axis machining. - Even in 5-axis machining which the orientation of the tool is often changed, it supports “Tool Center Point control l” that activates according to the commanded path.

There is no need to recreate the NC program whenever a machine, workpiece installation location and a tool length are changed.