Products

Version comparison : V.15.0

Contour Machining and Corner R Machining

A function was added to enable output of a corner R machining (contour) path to the contour semi finishing machining and contour finishing machining.

This eliminates the extra load for corner R machining that is applied prior to contour machining, thereby reducing the number of machining operations.

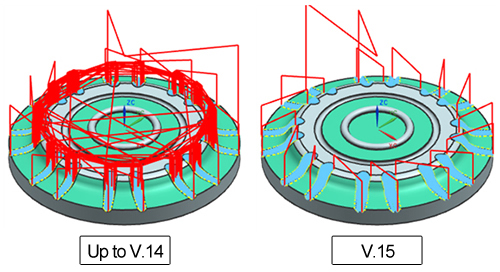

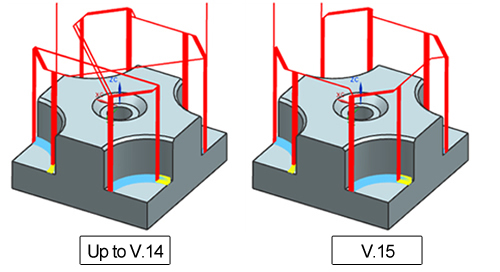

Improved Relief Operation

In Contour Machining, the relief operation with machining sequence area priority has been improved.

The movement (rapid traverse) distance between machining sequence areas (machining parts) has been minimized.

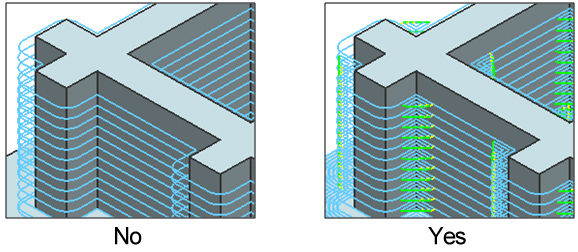

Along-area" of CR Machining Mode

In Corner R Machining, the relief operation for Along-Area mode has been improved.

The movement (rapid traverse) distance between machining parts has been minimized.

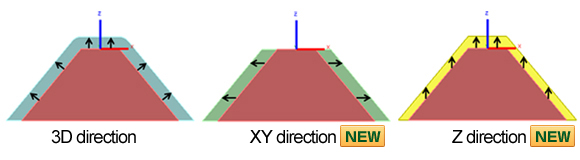

Adding the Finish Allowance Parameter Function

In addition to the conventional 3D directions for finishing allowance, the XY direction and the Z direction became available.

The offset face and check face can be specified.

Reuse of Intermediate Files

This function reduces the machining re-computation time by saving the files that are created during the computation without deleting them.

Effective with especially "Relief Height" and "Parameter of the tool number".

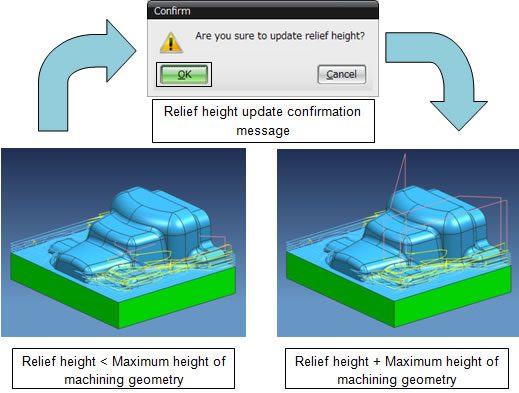

Adding a Relief Height Automatic Update Function

A function has been added so that the relief height is automatically updated to the "maximum height of machining geometry + relief amount" when the relief height is less than the maximum height of the machining geometry.

When the process start/end point is lower than the maximum height of the machining geometry, a warning message is displayed.