This function concept is “Anyone can create NC data of 5 axes machining easily”.

It creates the NC data of 5 axes machining as operating the 3 axes CAM.

To provide a system which can switch an operating environment according to a user’s skill.

Convenient Function for 5-Axis Machining

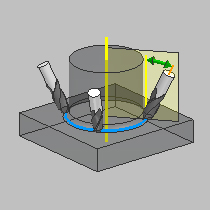

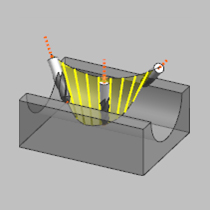

Tool Pre-View

Tool Pre-View try and error on Tool axis control Window

It makes easy to find the point or the axis without collision before calculation.

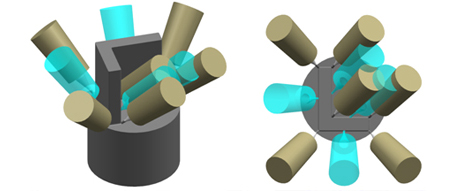

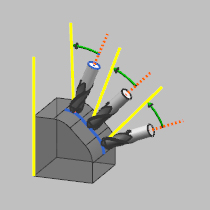

Add an Axis Reference Method for the Axis interpolation

Adding a posture to interpolate between selected locations easily.

Since it is possible to directly locate tools and operate intuitively,complicated operations, such as drawing axis lines for the tools and entering values, etc are unnecessary.

Brown: Specified axes , Light blue: Supplemented axes

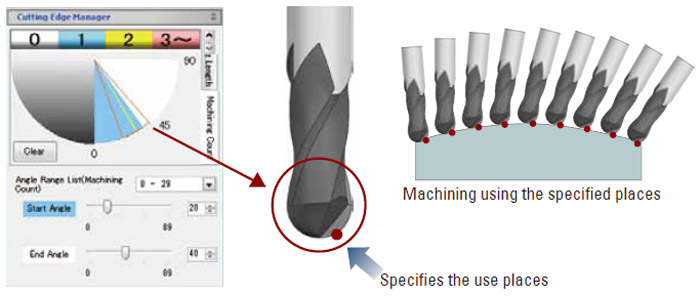

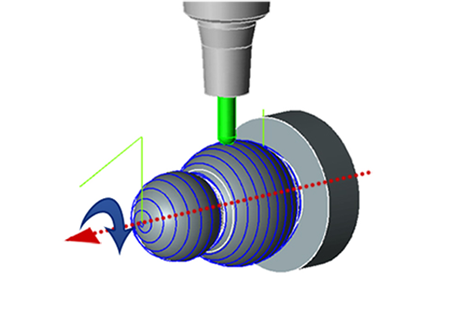

Cutting Edge Manager 5-Axis

This function allows the user to specify which area of the tool to use for machining.It is possible to estimate the level of wearing for each area of the tool from its number of use and cutting distance and to machine using the less worn area.

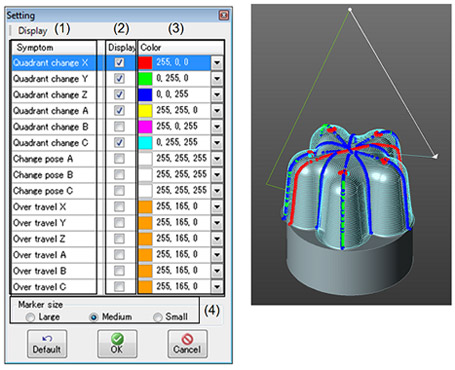

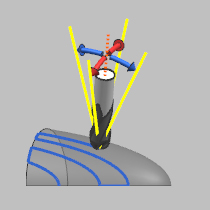

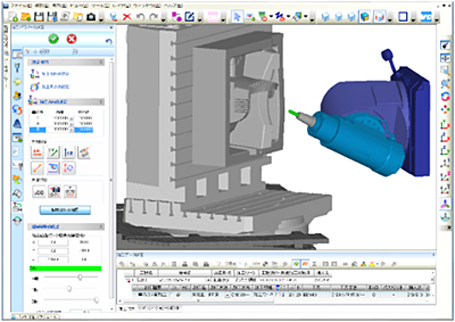

Path Analyzer

Using to find root causes of failures, such as lines on machined surfaces caused by characteristics of the machine or programs.

By using this before machining, avoiding such failures is expected.

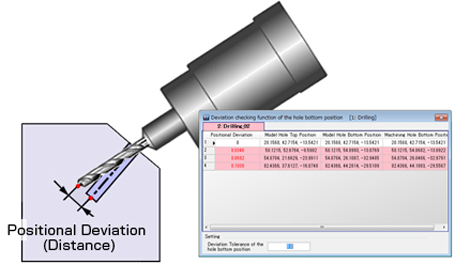

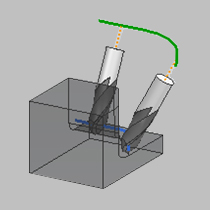

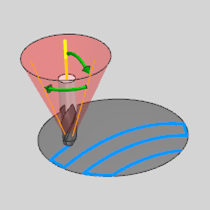

Error Check of the Hole Bottom Position for Drilling

It is possible to check the error amount of the hole position beforehand.

In accordance with the checked amount of deviation, it can be examined whether to implement the machining by this method or by other method

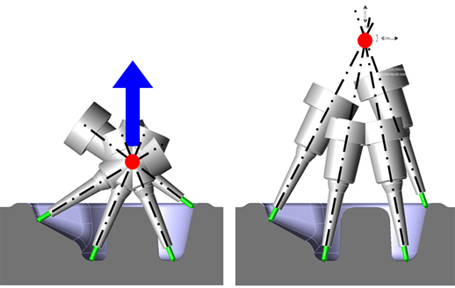

Determines the tool orientation automatically

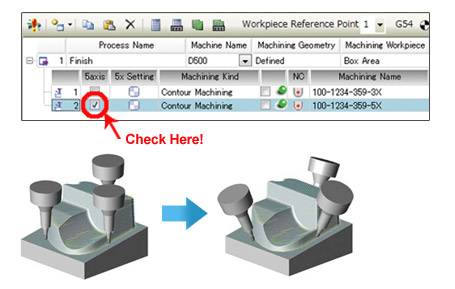

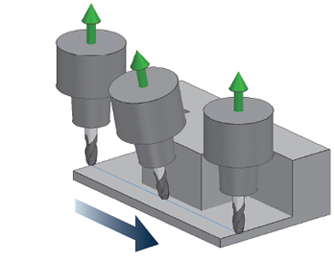

Simple Mode

One-click 5-axis machining

Toolpaths for simultaneous 5-axis machining can be generated from 3-axis machining settings by simply entering one check mark.

Automatic interference avoidance

When the tool and interference check model are specified, this function automatically tilts the tool axis to avoid interference.

Detailed Mode

Tool axis control

The tool axis direction can be specified in different ways to match the machining details. Interference avoidance is automatically provided.

Secure 5-axis machining

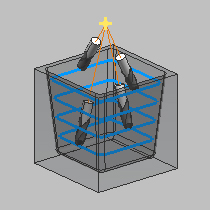

Tool Usage Range Setting 5-Axis

Use the location where the machining of the tool can be performed.

Setting is a combination of “Tool Bottom Face” and “Cutting Edge Length”.

Much safer rough machining in simultaneous 4 and 5-axis.

Tool Bottom Face

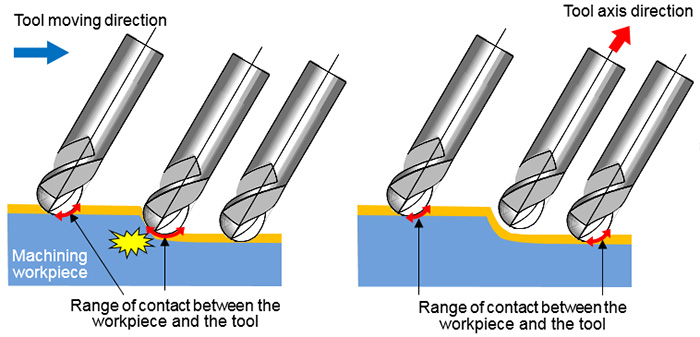

In [Tool Bottom Face], create the tool path that avoids the contact between the tool bottom face and the machining workpiece.

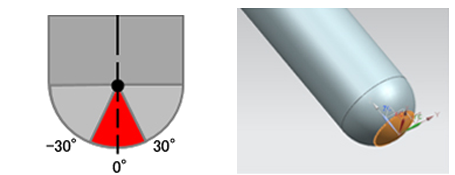

Angle Specification

When the tool is a ball end mill, and TA ball, specify the range of the bottom face by angle, and judge the presence of tool load by contacting with the workpiece in the range.

* Ball End Mill

Contactable

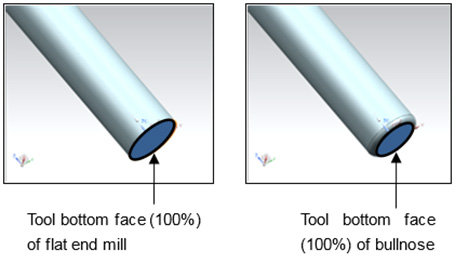

As for the Flat End Mill, Bullnose, and Round Insert FM, specify the rate (%) for the entire tool bottom face within the range and judge the presence of the tool load.

Example) Tool bottom face and workpiece comes in contact

Relief the tool to the tool axis direction, and avoid the machining on the tool bottom face.

Cutting Edge Length

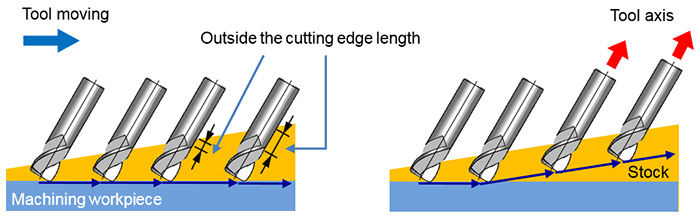

Specify the tool which is to be used in machining, avoid the shank to come in contact with the workpiece.

Example) Part without cutting edge length of tool comes in contact with the machining workpiece

Relief the tool in the tool axis direction and avoid the machining of the part without edge.

4-axis Movement Control

Easy to set up Simultaneous 4-axis Machining

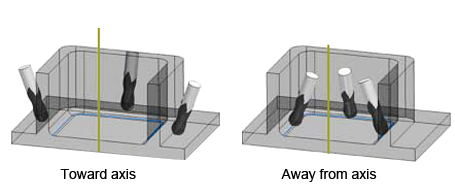

Relative to axis

Specifies an axis that serves as the reference for rotation, and machining is executed while maintaining a constant angle between the tool and the reference axis.

4-axis Movement Control

Specify one axis for rotation axis to be used during machining and perform the machining of simultaneous 4-axis.

Support for 6-axis 5-Axis

Meeting Individual Needs.

The machine axis can be registered up to maximum 6 axis.

Easy 6-axis data setting.