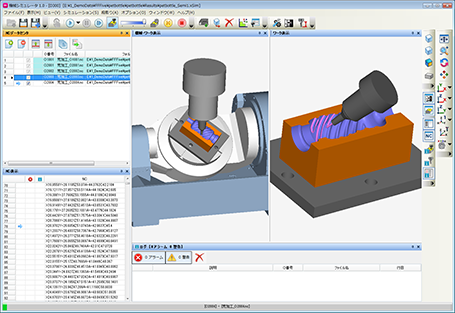

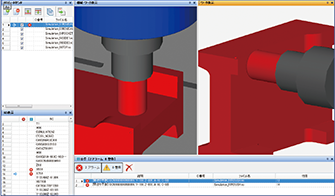

Machine simulation operates with “NC program” used in an actual machine.

This function enables simulations up to 5-Axis simultaneous machining using “NC data”, as well as “detection of interference with machines” and “verifications of insert statements” not possible with simulations using “CL data”.

Easy Operationality

The NC data generated in FFCAM can be simulated directly.

The verification work of dry run can be reduced drastically and the operation rate of machines can be improved maximally.

The confirmation of an behavior as same on PC as in machine

It is difficult to imagine the machining behavior with just only checking the NC program by simultaneous 5-axis machining unlike 3-axis machining.

The complicated behaviors such as indexing machining or simultaneous 5-axis machining can be verified during checking a realistic machining simulation before an actual machining.

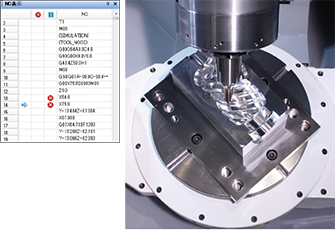

The realization of the safe simultaneous 5 axis machining

The collision risk in 5-axis machining becomes higher than in 3-axis machining for using more axis number in the machine.

This feature supports the simulation of multi-axis machine up to 5-axis with “NC program”.

It checks errors and collisions with “NC program” used the actual machine and prevents the collision risk.