Products

Version comparison : V.19.0

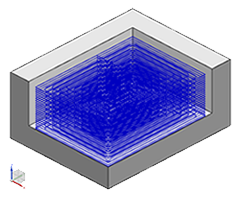

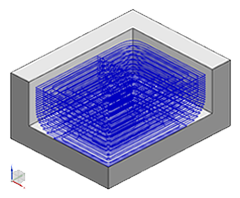

Machining FunctionContour Face Cut Machining / High-feed Machining

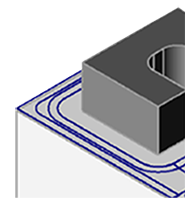

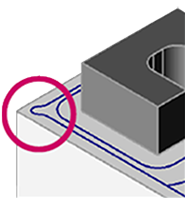

The exclusive cutter paths are generated and output for "High-feed Machining" with utilizing the characteristics of the high feed milling cutter.

Machining time is reduced with the best cutter paths.

Comparison

| Follow | Follow (High-Feed Machining | |

|

|

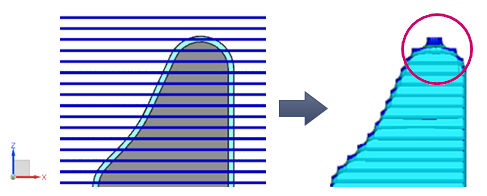

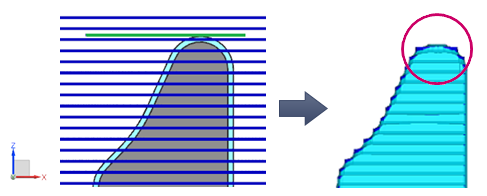

Modified tool path is output to pass through the uncut portions. Pick width in XY direction is also adjusted. |

| Follow | Follow (High-Feed Machining | |

|

|

Forward and reverse tool path that passes through the center of uncut portions is output. |

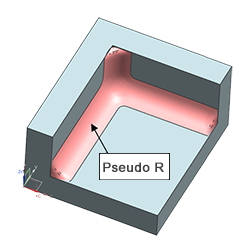

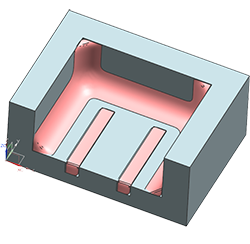

Machining FunctionAdd of Pseudo R Function

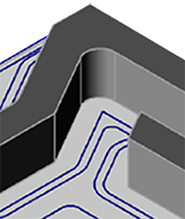

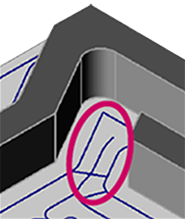

Outputs the tool path by adding R-shape corners to the concave angle portions of the machining geometry.

Reduces the load of tools when using the tools in R corners and deep grooves for rough machining. Also, users can omit the addition of R-shape corners during modeling.

Image of Pseudo R Addition

| Corner R portions | Deep groove portions |

|

|

Examples of Tool Path Outputs (Corner R Portions)

| Without pseudo R addition | With pseudo R addition |

|

|

Machining FunctionAdd of the Model Vertex Auto Recognition Function

Automatically recognizes the machining geometry vertices and adds the tool path of rough contour machining to its Z level.

Reduces the uncut portions between contour steps at the machining geometry vertices to prevent holder interference.

This function can be used for "Contour Rough Machining", "Contour Semi-Finish Machining", and "Contour Finish Machining".

Normal Contour Machining |

|

Contour Machining Using [Model Vertex Auto Recognition] Function |

Green line : Tool path added by [Model Vertex Auto Recognition] function |

SimulationAdd of New Functions to CSG Data Output Function

It corresponds to Professional 6 (Pro 6).

Professional 6 : Advanced control device designed to maximize mechanical performance.