FFCAM 2025 New Function

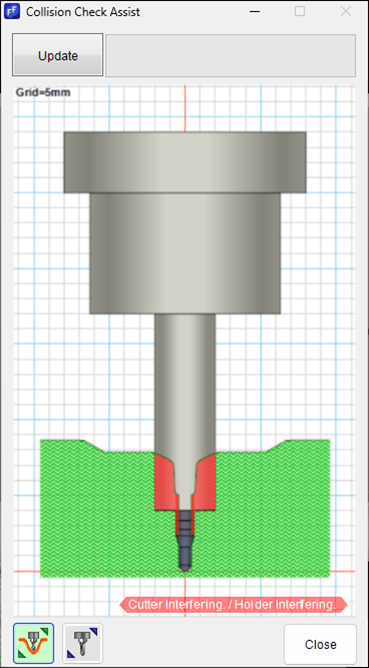

[Tool Setting] Collision Check Assist Function

This function overlays the tooling and the “interference area,” enabling you to detect potential collisions between the tooling and the model. By using this function, you can select interference-free cutters and holders before completing path calculation and simulation.

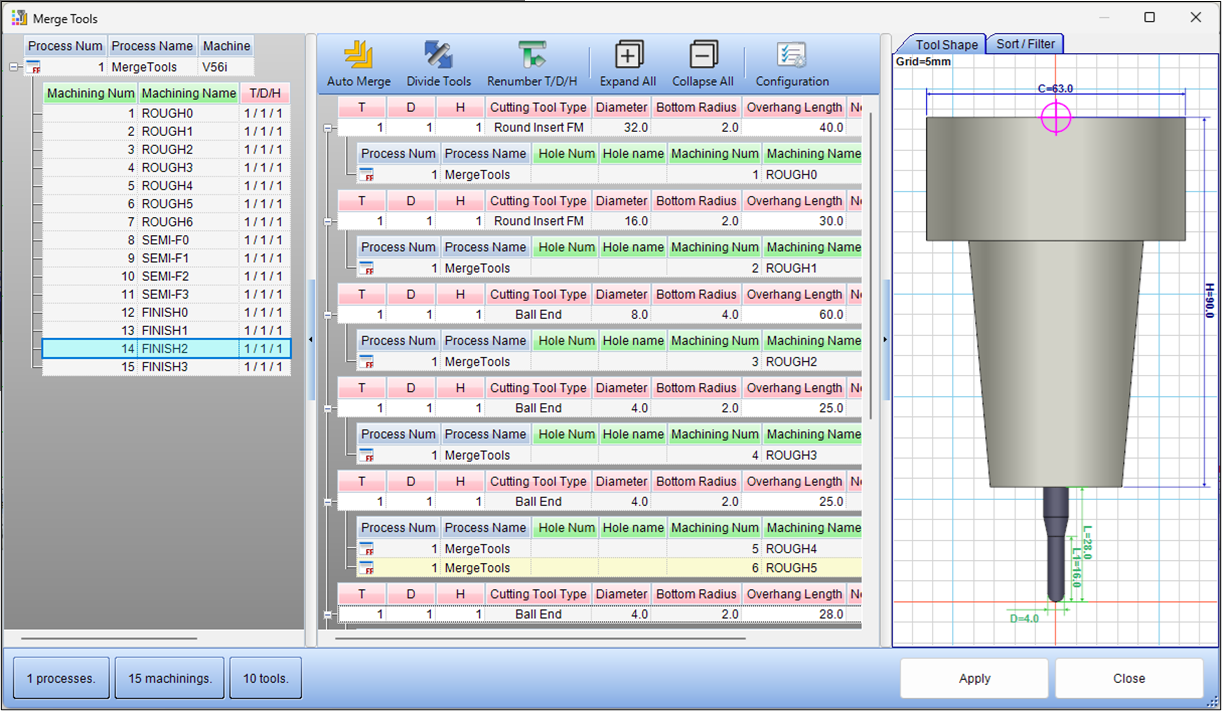

[Tool Setting] Tool Merge Function

This function allows you to manage machining data for each tool setting in a list format.

For example, it helps you identify cases where the same tool is used with different overhang lengths. When multiple entries have similar overhang lengths, they can be easily unified. By merging tool setting details across machining processes, you can reduce the number of tools that need to be prepared.

[Machining Setting] Automatic Color Filter Settings Now Supported in “Specify Contour Projection Machining”

In previous versions of FFCAM, when a color filter was applied to the machining area of machining data registered in the user database, copying and using that data would automatically apply the area settings to regions with the specified color.

This function is now also available with [Specify Contour Projection Machining]. When you define the contour and projection surfaces using a color filter in this function and register the data to the user database, the contour and projection settings are now automatically applied when you copy and reuse the data.

[Index Machining] Adjusts Input Angle to the Minimum Allowable Unit for Processing

When performing [Machining Direction] for index machining, if the angle input value is smaller than the minimum set unit of the machine, FFCAM will automatically adjust the value.

[Screen] Added a Function to Easily Check the Machining Area

A function has been added that allows you to display machining areas on the model by simply selecting each machining data item in the [Machining Data Selection] list.

Now you can easily check the machining area of each machining data item without opening the [Machining Parameter Setting] screen.

[User Database] Checks for Duplicate Process and Machining Names

Previously, when registering process or machining data from the [Machining Data Selection] list to the [User Database], it was not possible to register data with the same process or machining name.

In FFCAM 2025, you can now change the name on the spot if there is a duplicate.

[Machine Parameters] Adding Machine Data to the Machine List

Four new machines have been added to the FFCAM list.

- V300

- V900

- a500iR

- DA500

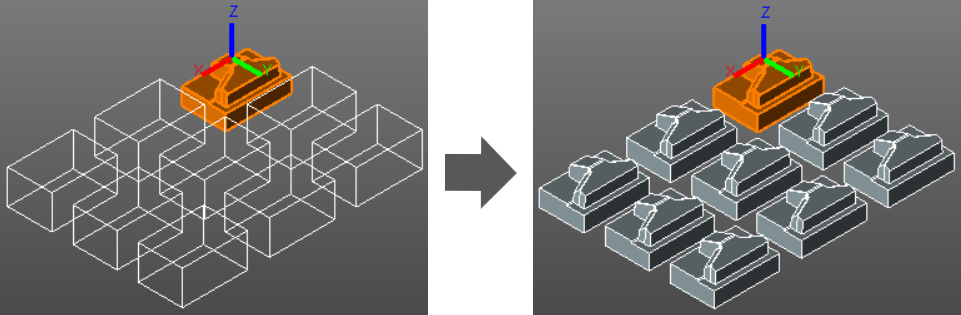

[Move/Copy] Copy Models to an Array

The [Copy array] function has been added to the “Move/Copy” function for models.

The [Copy array] function is a function that makes multiple copies of a model aligned in a grid pattern, according to the number of items specified in the X and Y directions.

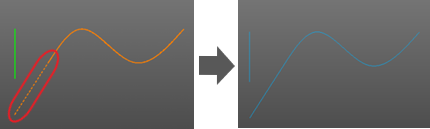

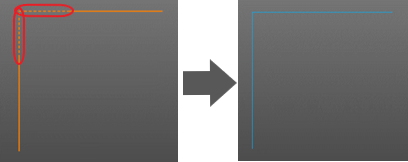

[Create Curve] Enhanced the Curve Extension Function

Previous versions of FFCAM did not allow target curves to be extended unless they directly intersected with reference curves.

In FFCAM 2025, a target curve can be extended to an expected intersection point even if it does not directly intersect another curve. Additionally, specifying both curves allows them to be extended simultaneously.

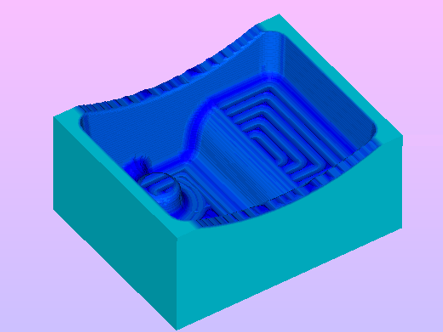

[Simulation] Faster display of Uncut Workpiece

When [Creat Data (Details), the rendering time when moving or rotating the viewpoint has been significantly reduced.

[Parameter macro] Enhanced functionality

FFCAM project file name can now be obtained

A variable to output the file name has been added.

Message output function can now be used with drilling

The function to display an error message when the condition is not met during calculation now support drilling.

Start and end points can now be set with a macro

In the “Process Start/End Point Settings” screen under “Process Setting,” process start and end points can now be set via macros.

Options

[Vericut Interface] Tool Setting Files Now Support New VERICUT Specifications

In line with the specification changes in Vericut 9.3, cutter parts are now output as a single part.