FFCAM 2021 New Function

Machine Functions

<Flat Face Machining>Improved Tool Path Outputs During Stock Machining

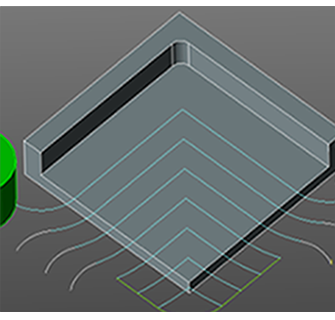

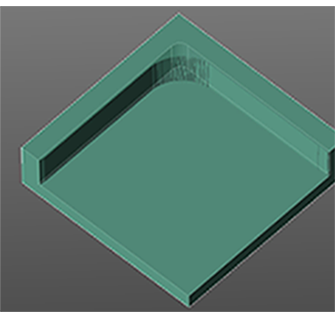

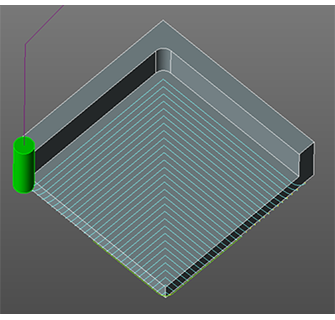

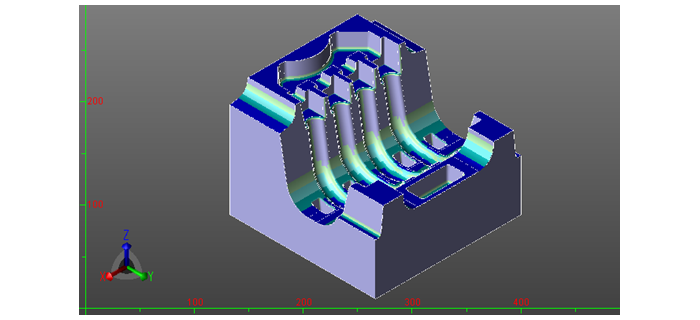

So far, stock machining of flat faces was only supported for updating the uncut geometry. Therefore, the tool path was also output for the flat surfaces.

In FFCAM 2021, in addition to updating the uncut geometry, the difference between the machining shape and uncut geometry is also identified, so that tool path is now output only for uncut parts.

The following is an example of loading the uncut geometry by flat face machining and outputting the tool path.

Load the above uncut geometry and compare the output tool path

The tool path is output only for the difference between the machining geometry and the uncut geometry.

[Cutter Setting] Changed the Min Value of [Maximum cutting angle of inclination] for Round Insert FM

In FFCAM 2021, the minimum value of the [Maximum cutting angle of inclination] for the Round Insert FM has been changed to “0.1” degree to meet the specifications of the tool manufacturer.

Improvement of Machining Parameter Macro

New macro definitions have been added to the machining parameter macros.

Operation・Window

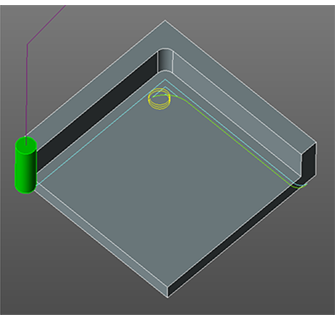

Addition of Tool Drawings and Coordinate Value Display Function

The tool position can now be checked in CL Display.

A function to draw the tool at the position on the CL path picked by clicking the mouse has been added in CL Display. A function to display the coordinate values of the point where you rolled over the mouse cursor on the CL path has been added.

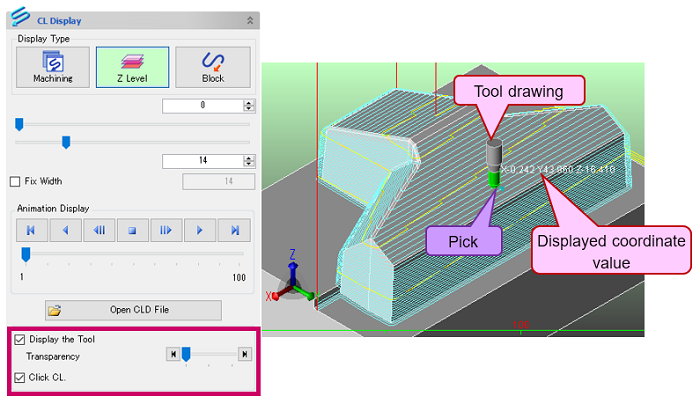

Multiple Color Selection Filter Added to the Element Selection Screen

In previous FFCAM versions, filtering could be executed by selecting only a single color, but with this new function, filtering can be executed by selecting multiple colors.

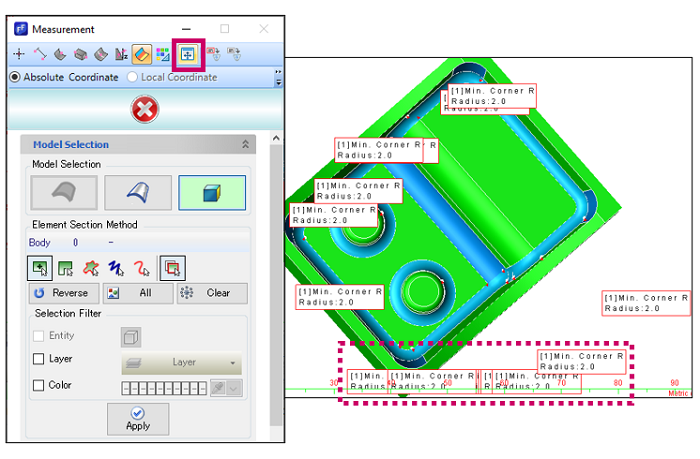

Addition of Function for Color Coded Display of Angular Deviation of the Model in the Measurement Screen

The function is now provided for the color coded display of the angular deviation of a specified face or the entire model geometry.

You can understand the angular deviation of the entire geometry at once, and use it as a reference for selecting the tool setting.

Addition of [Fit of the measurement result] Function button to the Measurement Screen

The [Fit of the measurement result] function, which used to be operated from the FFCAM menu or toolbar, can now be operated from the [Measurement] screen as well.

You can now execute the [Fit of the measurement result] function more quickly.

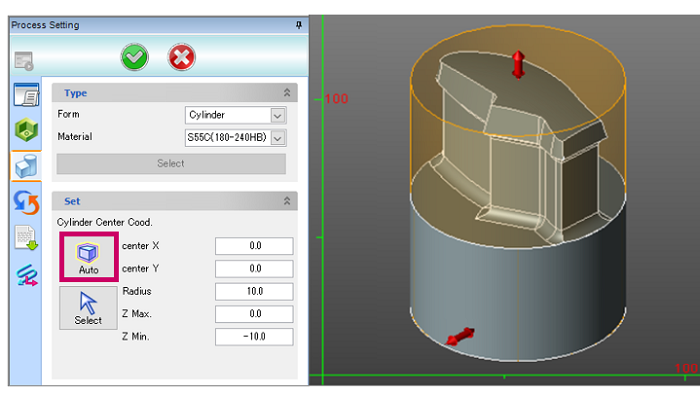

Addition of Automatic Acquisition Function for “Cylinder” in Set of Machining Workpiece

A Function to obtain the geometry automatically has been added to “Cylinder” in [Set of Machining Workpiece].

Like the auto acquisition function in [Box area], the cylindrical geometry can be automatically acquired and defined.

Improved Tab Display in the Process Setting and Machining Parameter Setting Screens

The icons of the tab have been improved so that they are highlighted when selected.

It is now easier to recognize the selected tab in [Process Setting] and [Machining Parameter Setting] screens.

Improved the Procedure for Opening Option Set Screen

The [Option Set Screen] can now be opened by double-clicking the file name “FFcam.dll”.

Improved Output Function in Sheet Name

Supported items for the Sheet name output function set in the [Option Set Screen] have been added.

In addition, restrictions and their automatic confirmation function have been added to the Sheet name output function.

Improvement of [Simulation/Repost] screen

The [Open a designated folder] button has been added in the [Simulation/Repost] screen.

You can also open the destination folder of the working file with a single click in the [Simulation/Repost] screen.

Improvement of the Maintenance – [Tool database] screen

The order of the list rows in the Maintenance – [Tool database] screen can now be changed as required.

Addition of Project Data Collection Tool

You can quickly collect project data when there is a problem with the data and it needs to be verified, or when you want to backup the project related data in the middle of work.