FFCAM 2016 New Function

FFCAM 2016 has been developed with focusing on user friendliness and considering to many users’ opinions. We believe that we can offer two different type operations depending on users. The easy and secure operations for beginners. The speedy and comfortable operations for experts.

Machining Functions

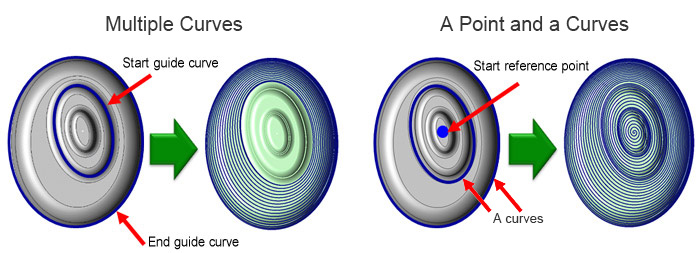

Enhancement in 3D Equi-Pitch / Close Machining with Multiple Guides

Multiple guide curves or a point and a curve(s) can be chosen. A cutter path of the spiral motion along the eccentric shape can be created.

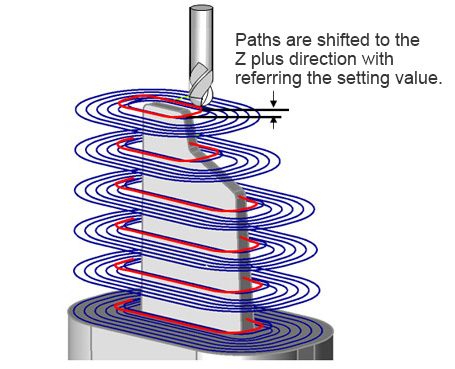

Additional functions in the thin rib processing

The function that the cutter path in the closest to the geometry is shifted to the Z direction is added. The function can reduce the tool load at the closest area of the geometry and offer the better machining surface.

GO1 output in Drilling

The Machining data of G01 can be output.(G73,G81,G82,G83,G85 and G89< only this option can be set as ON or OFF >).

Drilling can be done by even the machine cannot use the FANU canned cycle.

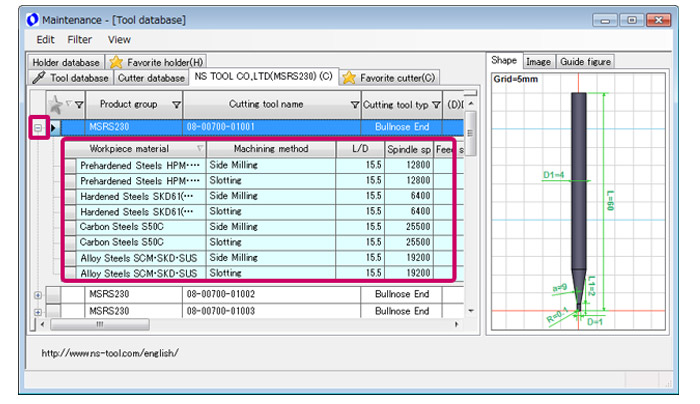

Tool Database Enhancement

Maker cutting conditions can be reviewed. You can review immediately whether the tool has the condition to match your machining way or not.

Operation

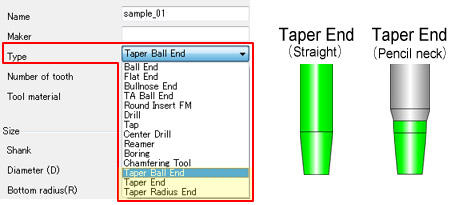

Tapered Tool Compatibility

The [Cutter edit] screen supports tapered tools. The latest machining conditions of tool manufacturers can be imported, and tapered tools can also be referenced.

Useful Function

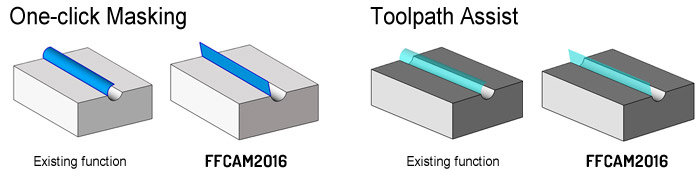

Expansion of One-click Masking and Toolpath Assist

A function to linearly extend arc faces using [Extension] of [One-click Masking] and [Toolpath Assist] has been added. This eliminates extended portions of arc faces from becoming under parts.

Simulation

Temporary stop during collision check at cutter Rapid Motion

Setting “Temporary stop” when collision is detected in [Collision check at cutter Rapid Motion] has been made possible.

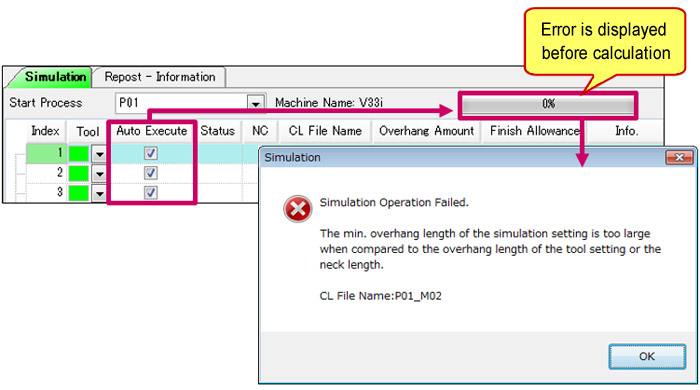

Enhancement of Overhang Length Calculate Function

The [Overhang Length Calculate] function has been enhanced according to the operations. You can check for interference position. If the [Overhang Length Calculate] setting is not appropriate, the cause will be displayed as an error at the start of calculation. Errors can now be checked before calculations, eliminating recalculation time.

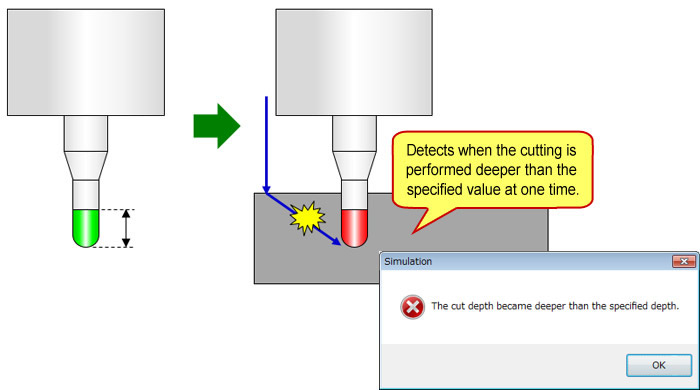

Add of Cutting Depth Calculation Function

Cutting Depth Check

A function which detects cuts deeper than the specified value and prevents collision into work has been added. Damage to the tool and spindle can be prevented by detecting cuts exceeding the expected depths. You can check the maximum cutting depth during machining.

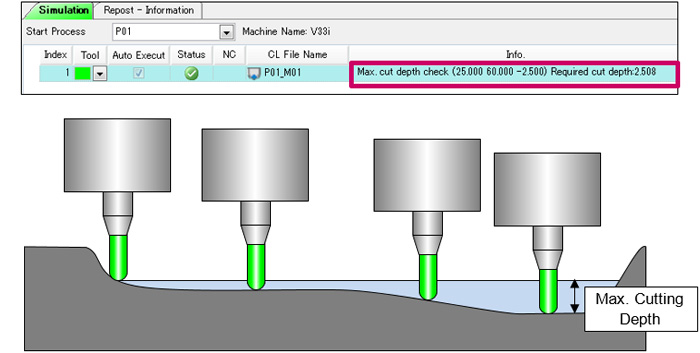

Calculation of Max. Cutting Depth

[Max. Cutting Depth] information is output.

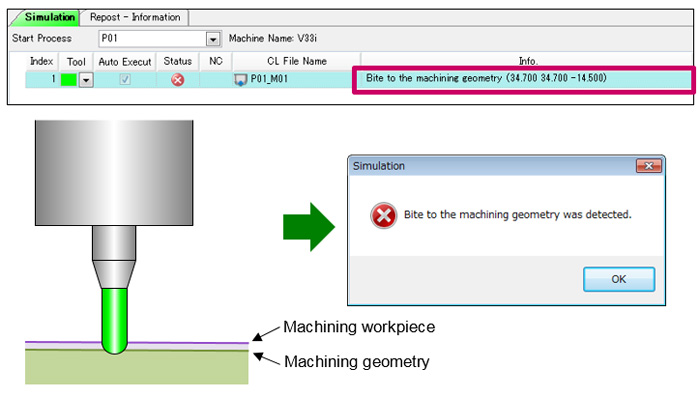

Add of Bite Detection Function to Machining Geometry

A function to detect bite when the geometry of the simulation results bites into the machining geometry has been added. It detects bite of the machining geometry by the machining workpiece.

Other Operations Can Be Performed During Simulation

Operations such as Machining Create can now be performed during simulation. The simulation calculation time can be used more effectively increasing the work efficiency.

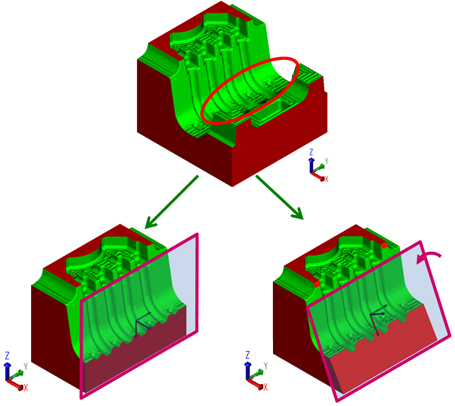

Add of Cross Section Display Function

A function to display the cross section of the simulation results has been added. This enables detailed parts to be verified more easily.

Right : Display by specifying the cross section direction, coordinates, and rotation angle.

Add of Cutting Results Display Function

The CL data with the interference and the position of interference are displayed on the screen. This function checks the causes for interference with both values and on the screen to enable measures to be taken efficiently.

- CL File Name

- Tool Name

- CL Information

- Interference position

- Interference information list

- Mark display setting

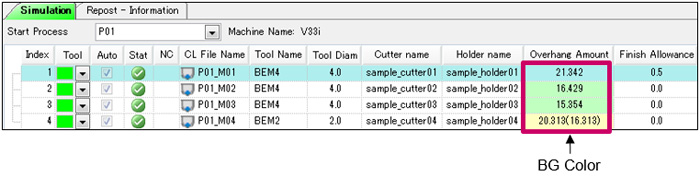

Improvement of Machining List

After [Overhang length calculation], the background color of the [Overhang Amount] area of the machining list will be changed. You can be decide whether [Overhang Amount] required or not.

Yellow : If the [Overhang Amount] calculated is longer than the tool setting.

Green : If the [Overhang Amount] calculated is shorter than the tool setting.

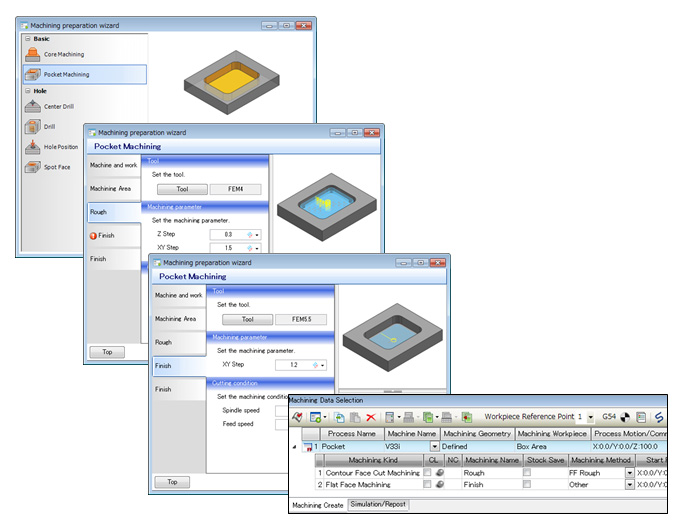

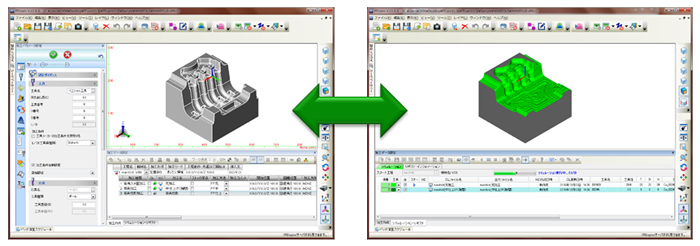

Machining Preparation Wizard Function

A new “Machining Preparation Wizard function” has been provided. This wizard helps beginners to carry out the required CAM settings in order and create machining processes. Existing users, to efficiently perform work by this function.