FFCAM 2020 New Function

Machine Functions

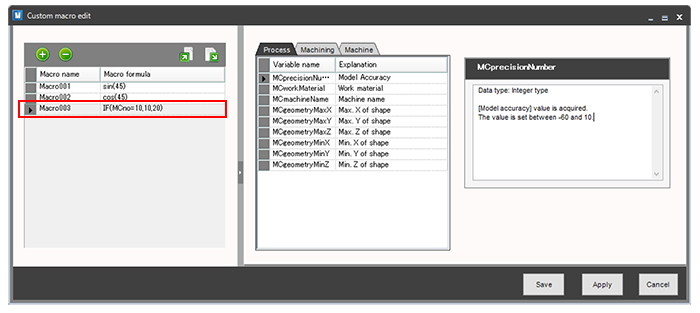

Automation of Machining Parameter Setting by Macro.

Automatically changes the value of the parameter whose value changes depending on the situation.

Example:

If the machine is “iQ300”, set the model accuracy to “-40”.

If the machine is “other than iQ300”, set the model accuracy to “-20”.

This function eliminates the need to re-enter values and prevents missed settings for related parameters.

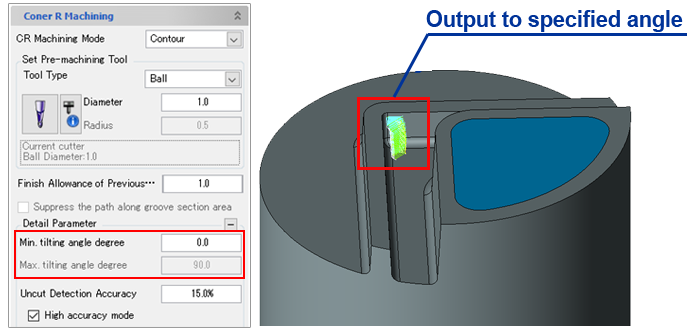

Added of “Tool Path Output Control Function by Tilt Angle”.

In the [Contour], [Angle-area] and [Pencil] modes of CR machining, a function to specify the output range of the tool path by the tilt angle of corners has been added.

The function allows you to create the tool path only in appropriate areas for each machining mode.

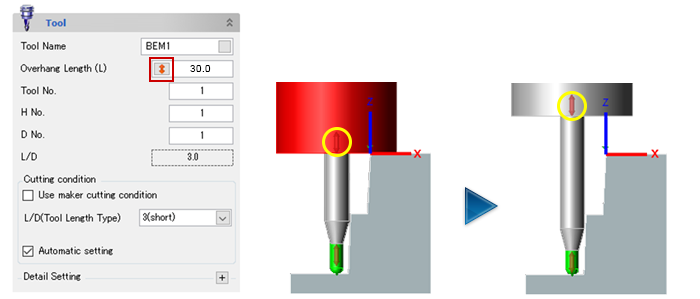

Added of Function to Set Overhang Length and Neck Length Using Mouse

This function allows you to visually set the tool length by using the tool shape drawn on the graphics window.

This visual setting eliminates trial and error in numeric input, allowing quick determination of tool length.

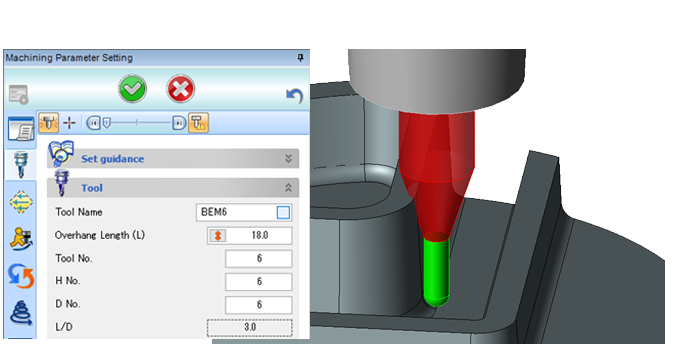

Added of a Function to Simplify the Interference Check Between the Tool and Machining Geometry

Draw the tool in red when there is interference between the tool and machining geometry during tool drawing has been added.

It is easy to check if there is any interference between the tool and machining geometry and prevents oversight of interference.

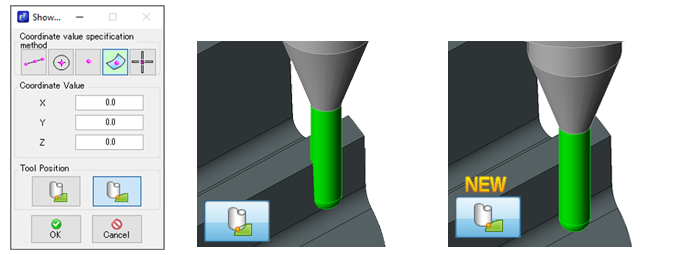

Added of a Function to Draw Tool Connection

A function is added to draw the tool so that it touches the specified point.

The [Tool Position] parameter can be select the position to draw the tool. You can select [Tip button] or [Contact Point button], two types of positioning methods.

In FFCAM2020, Interference of tools and holders can be confirmed more accurately using this function.

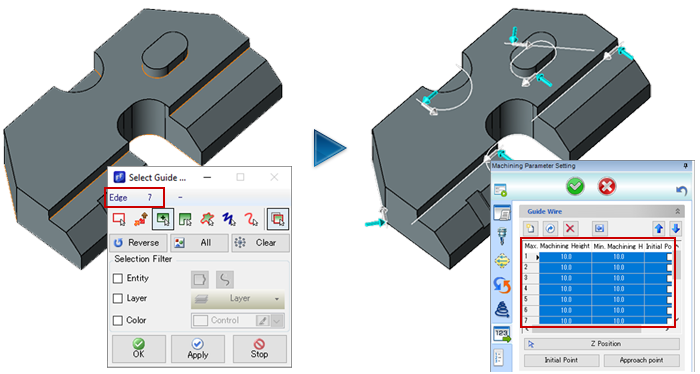

Added a Batch Registration Function for Multiple Guide Wires

In FFCAM2020, you can now select multiple guide wires at once by selecting the range.

When the number of wires are more, the number of steps and time required to select them can be reduced.

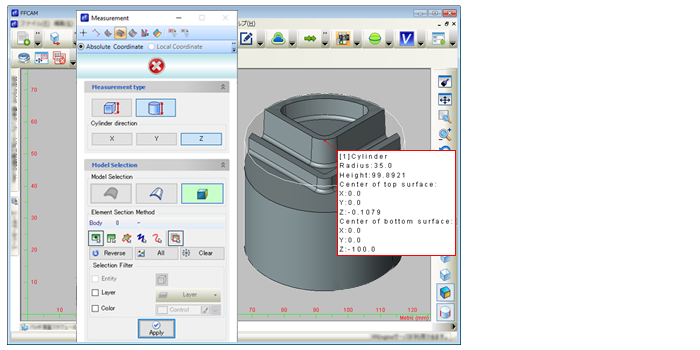

Added of a Function to Measure the Cylinder Area of Geometry

In FFCAM2020, the function to measure the geometry size in the cylinder area has been added, and the required numeric values can be obtained efficiently.

Improved Tool Path Calculation Speed for Contour Machining

The function has been improved for faster calculation of tool path when “Contour Corner R” and “Outside area infeed of contour infeed” are set in contour machining.

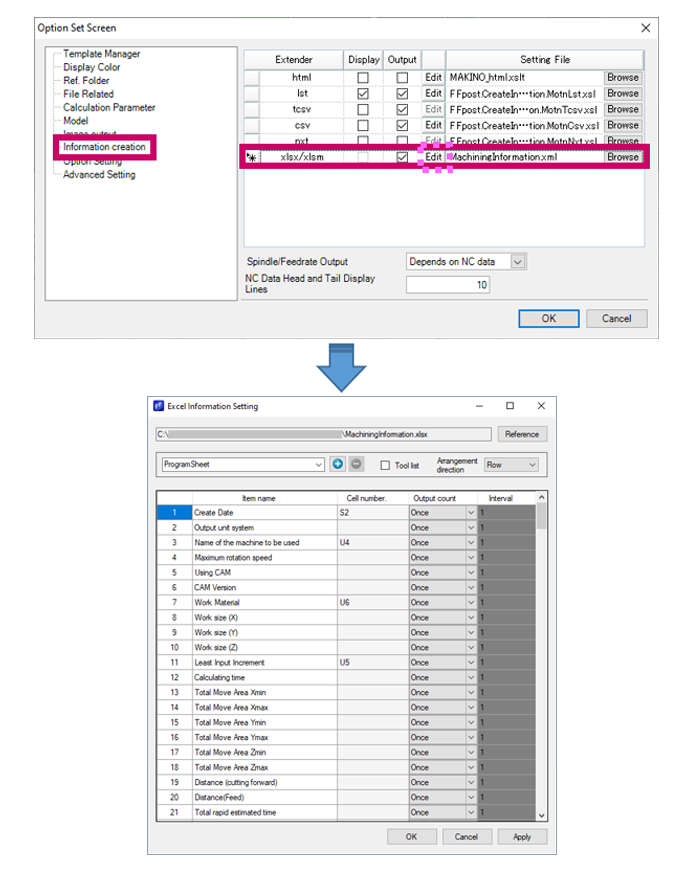

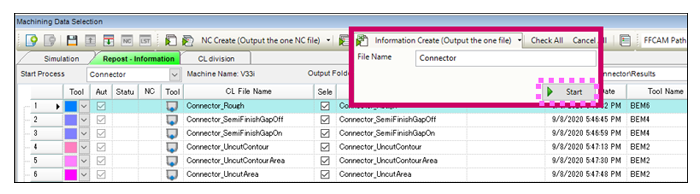

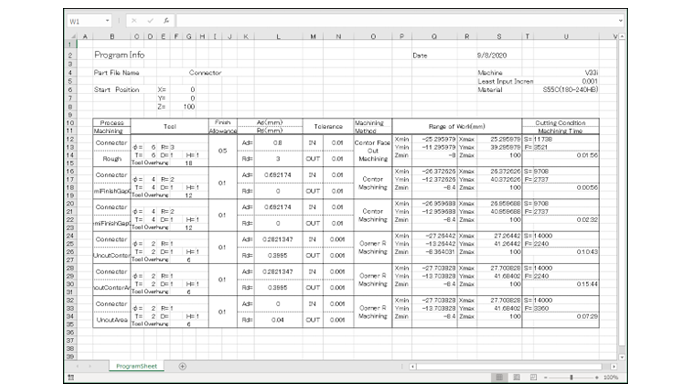

Function to Export the Machining Information to Excel

In addition to the existing Machining Information output function of FFCAM, the new function allows the output of Machining Information in Excel format, enabling detailed customization.

The Excel Machining Information that is set will be output when the “Information Create (Output the one file)” function in [Repost – Information] is used.

Ex.: Excel Machining Information that is output

New Definitions for Parameter Macro Definition Function

- Macro variable types that can be defined and parameter types that support macro settings have been increased in the parameter macro definition function.

- Support for [Pre-machining Tool] for Corner R Machining.

- Support for stock file specification.

Updates Changes in Content of Process List after Application of Parameter Macro

When a parameter macro is specified in the process setting, process list information in [Machining Data Selection] is updated after path calculation.

Since items that allow you to set parameter macros have been added to the process setting, the contents are updated in the process list.

The following process settings have been added to the setting items of parameter macro.

- Process Setting (Milling)

- Process Setting (Drilling)

Operation

Added of Main Program Creation Function

In FFCAM2020, the function to easily create a main program on the [Report Information] screen has been added.

You can create a Main Program that uses a dedicated POST.

※Customers limited you have a POST for Main Program

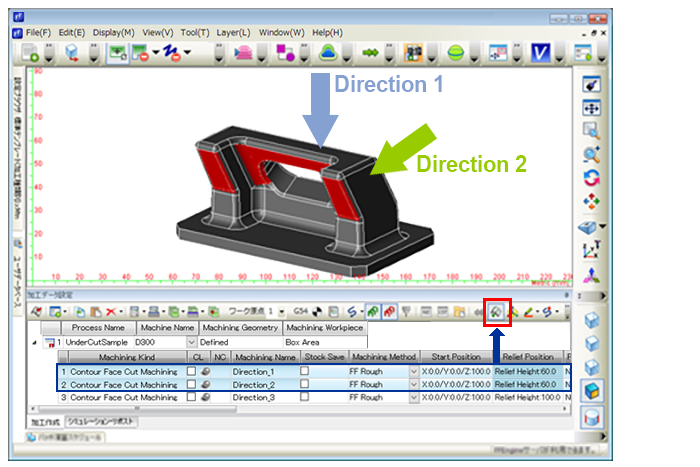

Added of the Under Cut Function for Multiple Machining

When executing display of under cut portions, if you select multiple machining or process (multiple processes), the under cut portions are displayed for the entire selected machining.

It is now possible to check under cut positions for multiple machining operations at once, making it easier to find areas that cannot be machined.

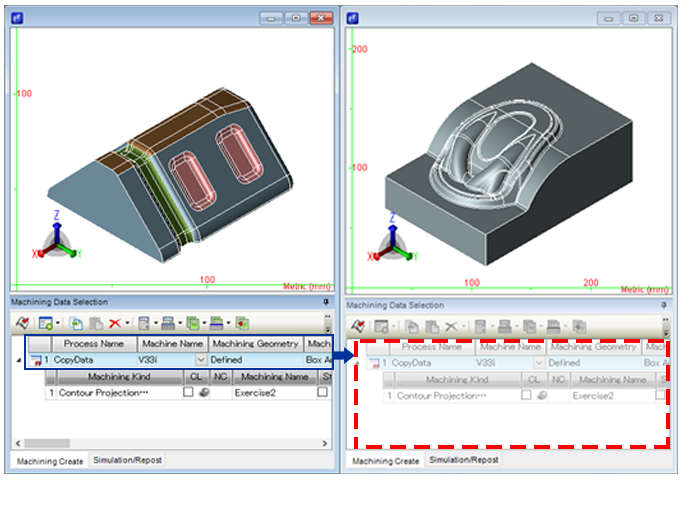

Improved Function to Copy Process and Machining Data Between Working Windows

In FFCAM2020, you can copy process and machining data even when the [Machining Data Selection] in the destination window is empty.

Added of Multiple Setting Value Copy Function on the Machining Data Selection Screen

The set values on the machining data setting screen can be copied simultaneously for multiple machining data.

Number of Comment Characters in [Process Setting] and [Machining Setting] Increased

The number of characters that can be entered in the comment fields of [Process Setting] and [Machining Setting] has been increased.

Comment up to 127 double byte characters or 254 single byte characters can be entered.

You can now enter more words in the comment field, such as, when parameter macros are set.

The number of characters has been increased for the following four comment fields.

- Processing Setting comment field (Milling)

- Machining Setting comment field (Milling)

- Process Setting comment field (Drilling)

- Hole Information comment field (Drilling)

Function to Check Duplicate Process and Machining Names during Path Calculation

Process and machining names can be set by the parameter macro. If process or machining names are duplicated, FFCAM may not complete the path calculation successfully.

Depending on the macro expression, process or machining names may be duplicated during path calculation. This function prevents such duplication.

The following process and machining names are checked for duplication

- Process name (Milling)

- Machining name (Milling)

- Process name (Drilling)

- Hole information name (Drilling)

- Machining name (Drilling)

Options

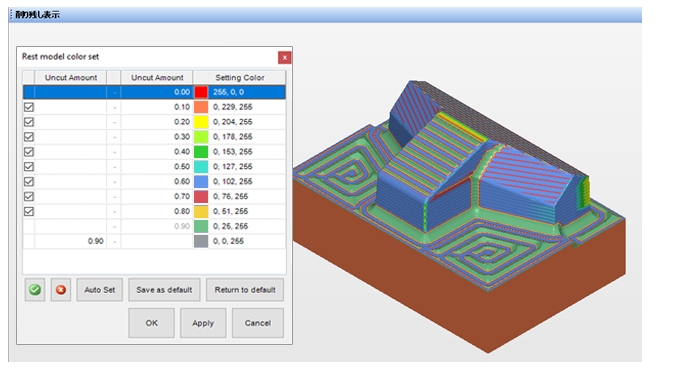

[Machine Simulator] Added the Function to Color-Code the Cut Rest of Cut Workpieces

The machine simulator provides a color-coded display of the cut rest amount after simulation, making it easier to check the machining results.